Geomechanics and Geotechnology Laboratory

The Geomechanics and Geotechnology Laboratory has over 30 years of activity and comprises three sections: Rock Mechanics, Applied Geomechanics, and Rock Cutting. It possesses considerable experience in research into rocks' physical, mechanical, and technological characterisation. The lab is equipped to perform tests on-site too, and it operates in numerical modelling, employing general-purpose calculation codes such as Flac®, Udec®, and Map3D® for stress-strain analysis in continuous and discrete structures using FEM, FD, BEM, and DEM techniques. It also uses specific calculation programs developed for analysis and data processing. This advanced equipment enables precise assessment of rock and soil properties, supporting research and practical applications in mining, civil engineering, and geotechnical studies.

RESEARCH EQUIPMENT

MTS servo-hydraulic testing system

MTS servo-hydraulic testing system

Unidirectional conventional loading machine

Unidirectional conventional loading machine

Conventional bidirectional loading machine

Conventional bidirectional loading machine

"Creep" test machine

"Creep" test machine

Linear dilatometer

Linear dilatometer

ILCM (Intermediate Linear Cutting Machine)

ILCM (Intermediate Linear Cutting Machine)

3D printer

3D printer

Prototyping Equipment

Prototyping Equipment

Digital Microscope Keyence VHx-7000

Digital Microscope Keyence VHx-7000

Shimadzu Microhardness Tester

Shimadzu Microhardness Tester

Shimadzu Microhardness Tester

Shimadzu Microhardness Tester

MTS Multipurpose servo-hydraulic testing system: this system is for static and dynamic tests with digital technology, 2700 kN, equipped with a load cell. It can perform various types of tests automatically or manually with different control parameters (load/deformation) in quasi-static, “fast” creep, and low-frequency dynamic conditions. Specific strain gauge transducer kits are available for uniaxial compression tests, tensile strength, toughness, and fracture propagation. It also features a 100 MPa triaxial confinement cell and heating apparatus for confined tests up to 150 °C, equipped with special longitudinal and circumferential strain gauges.

Unidirectional conventional loading machine: this machine is for compression only, 3000 kN, and is equipped with load cells and a triaxial cell.

Conventional bidirectional loading machine: this machine handles compressive and tensile strength, 50 kN, and is equipped with load cells and a triaxial cell.

Shear machines: the laboratory has shear machines with 500 kN and 50 kN actuators (horizontal and vertical).

"Creep" test machine: it applies a 500 kN load for "slow" creep tests

Linear dilatometer: a linear dilatometer for NX specimens operates up to 1500 °C.

ILCM (Intermediate Linear Cutting Machine): the ILCM is designed to conduct a realistic test for evaluating the rock-tool interaction process. It determines the forces exchanged during excavation between a tool (sliding or rolling) and the rock using a triaxial cell. The tool is a disc with the same characteristics as those mounted on the head of a TBM (Tunnel Boring Machine), and the sample represents the rock to be tested. Varying geometric parameters like the distance between the grooves and the depth of cut allow for the evaluation of the spacing/penetration ratio to optimise the specific excavation energy.

Digital Microscope Keyence VHx-7000 is the world's first 4K resolution microscope. The camera, equipped with a 12.22-megapixel sensor, features automatic zoom recognition and a motorised turret for automatic lens switching. It covers a zoom range from 20x to 6000x.

Shimadzu Microhardness Tester: equipped with two indenters for conducting Knoop (HK) tests (rocks) and Vickers (HV) tests (metals), with the capability to apply 16 different loads, ranging from 9.807 mN to 19.61 N, and a variable load application time from 0 to 999 seconds. Automatic reading is performed through image analysis captured by a digital camera.

Press Frame Belladonna for Soil Testing – Capable of applying a maximum load of 20 kN for soil strength and deformation analysis.

Prototyping equipment: the laboratory is equipped with instruments suitable for the production of prototypes (3D printer) and their finishing

Cerchar Abrasivity Index

Cerchar Abrasivity Index

Permeameter

Permeameter

Punching test

Punching test

basic kit for geostructural survey

basic kit for geostructural survey

Press frame for soils

Press frame for soils

Monitoring Systems

Monitoring Systems

Numerical Modelling

Numerical Modelling

Moreover, the laboratory provides a comprehensive range of testing tools for determining critical geotechnical properties, including:

Cerchar Abrasivity Index (CAI) Tester: this tool measures the abrasiveness of rock samples, which is essential for predicting tool wear in excavation and drilling operations. Punching Test (Point Load Test): it determines the strength index of rock specimens for classification and geotechnical assessment. Pulse Bar Test: it evaluates dynamic mechanical properties and impact resistance of geomaterials. Basic Kit for Geostructural Surveys: Profilometer—Records surface roughness and discontinuities; Compass – Facilitates orientation and structural mapping; Sclerometer (Schmidt Hammer) – Measures surface hardness of rock and concrete; Optical Distometer – Enables precise distance measurements in field surveys; Permeameter (Variable and Settled Load) – Determines soil and rock permeability under controlled conditions, aiding in hydrogeological and stability assessments. Freatimetric probe. Inclinometric and assestimetric probe Slope Indicator.

On-Site Stress State Monitoring and Geomechanical Measurements: the laboratory is equipped with specialised instruments for in situ testing, enabling direct assessment of rock mass properties under natural conditions. Available equipment includes Simple and Double Core Drills, which Extract rock samples for laboratory analysis and classification; Devices for Natural or Induced Stress Measurement, according to Two-dimensional and three-dimensional (doorstopper, CSIRO) stress release techniques for assessing in situ stress conditions; Hydraulic Fracturing Tools, used in small-diameter boreholes to evaluate rock stress and permeability; Flat Jack Stress Measurement System, comprising pumps and displacement transducers for measuring in situ stress and rock deformability; Plate Load Test Equipment, to determine deformability and bearing capacity of rock and soil.

Tunnel and Infrastructure Monitoring: convergence Measurement Tape Tracks tunnel deformation and stability; Piezometric and Thermometric Probes; Total Radiation Thermometer Measures surface temperature in geological and engineering applications; Rock Wall Heating Equipment is used for on-site thermal conductivity assessments.

Study of rock-tool interaction at a small scale: knoop micro-hardness correlates with stone workability and can be used to predict rock-cutting tool (widia, steel, diamond) interaction. Cutting performance is related to the rocks' characteristics, and micro-hardness measures can provide helpful information about their workability. The mineralogical composition of rocks can be correlated with excavation performance, and microscopic analysis can investigate the wear processes of different kinds of tools during excavation.

Geotechnical and Environmental Monitoring Systems: custom-Developed Sensors and Wireless Data Acquisition Systems – Designed for real-time monitoring of natural and artificial structures, providing crucial insights into stability and long-term performance.

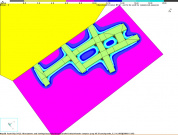

Numerical Modeling and Computational Analysis: the laboratory emphasises advanced numerical modelling and automated calculations for geomechanical and structural analysis, utilising General-Purpose Computational Tools, such as: FLAC®, UDEC, Map3D® – Used for stress-strain analysis in continuous and discrete structures, employing Finite Element Method (FEM), Finite Difference Method (FDM), Boundary Element Method (BEM), Discrete Element Method (DEM), Custom Software for Data Processing and Analysis, Geological Structural Survey Interpretation, Rock Mass Stress State Determination, Statistical Analysis and Data Visualization, through general-purpose computation tools for mathematical modeling, graphical representation, and database management.

Particle Size Testing: To ensure compliance with international standards, the laboratory is equipped with precision instruments for particle size analysis and specimen preparation, including Particle Size Distribution Analysis, Electromechanical Sieves, Standard Sieves, used for granulometric classification of soils and aggregates, and ovens.

Motorised Base Desk for Sliding Tests (Tilt Test), to determine friction angles along discontinuities in rock and soil specimens.

Sample Preparation Equipment: Disc Cutting Machine – Cuts rock and concrete samples to precise dimensions; Core Drilling Machine – Prepares cylindrical samples for strength and permeability tests; Grinding Machine – Polishes specimen surfaces for accurate testing and microscopy.

| Type | Research laboratory |

|---|---|

| Phone | Laboratorio +39 011 0907676 - Ufficio +39 011 0907615-7655 |

| marilena.cardu@polito.it | |

| Staff |

|