Road Materials Laboratory

The Road Materials Laboratory of DIATI operates in the field of road infrastructures by means of teaching activities, research investigations, technical and scientific consultancies, and third-party services in accordance with art. 49 of the Consolidated Act - Royal Decree 1592/33. It is an official laboratory as identified by art. 59 of the D.P.R. n. 380/2001, authorized to issue certificates and test reports valid for the purpose of testing construction products.

Rolling Thin Film Oven (RTFO)

Rolling Thin Film Oven (RTFO)

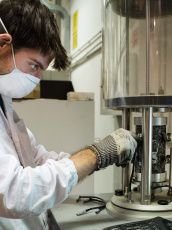

Static press 50 kN

Static press 50 kN

Servo-hydraulic universal testing machine 15 kN (AMPT)

Servo-hydraulic universal testing machine 15 kN (AMPT)

Automatic furnace analyzer

Automatic furnace analyzer

Sieves for particle size analysis

Sieves for particle size analysis

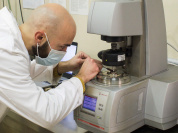

Rotational Shear Rheometer (DSR)

Rotational Shear Rheometer (DSR)

Iatroscan

Iatroscan

Materials for road pavements

Materials for road pavements

Wheel tracker

Wheel tracker

Rheology room

Rheology room

TEACHING ACTIVITIES

The teaching activities carried out in the laboratory have the function of supporting the academic courses offered by the scientific sector ICAR/04 of the Politecnico di Torino. These include guided tours, supervised laboratory exercise sessions and internships.

For undergraduate students, proposed activities focus on the basic characterization of materials employed in the construction of transportation infrastructures, including bituminous binders, granular materials and soils. Equipment that is available for these activities includes:

- Penetrometer apparatus for binder and soil testing

- Ring and ball apparatus for softening point measurement of bituminous binders

- Sieves for particle size analysis

The laboratory activities offered to Master’s students are related to quality control and performance characterization of materials for roads, railways and airports. Among the equipment dedicated to teaching, the most important is the following:

The Road Materials Laboratory also supports PhD courses on the rheology of complex materials, with the use of the following equipment:

RESEARCH ACTIVITIES

Experimental scientific research activities are mainly developed in the field of materials used for the construction of road infrastructures, with an emphasis on the design of innovative and sustainable materials, and on the development of test protocols and new technologies. The laboratory also offers the possibility of developing experimental theses.

Among the laboratory equipment used in research, the following can be mentioned:

- Iatroscan

- Ultrasonic sonicator

- High-shear laboratory mixer (Silverson)

- Low-shear laboratory mixer

- Pressure Ageing Vessel (PAV)

- Rolling Thin Film Oven (RTFO)

- Rotational Shear Rheometers (DSR)

- Bending Beam Rheometer (BBR)

- Brookfield Viscometer

- Automatic heated 80 litre asphalt mixer (BBMAX)

- Wheel tracker

- Slab compactor (BBPAC)

- Proctor compactor

- Marshall compactor

- Gyratory shear compactor

- Static press 50 kN

- Servo-hydraulic universal testing machine 15 kN (AMPT)

- 10 kN servo-pneumatic universal testing machine (UTM-10)

- Automatic furnace analyzer

- Environmental simulation chambers

- Shear box apparatus (ASTRA)

The main equipment used for field activities includes:

- Dynamic plate (Light weight deflectometer)

- Static plate

- Dynamic Cone Penetrometer (DCP)

- In situ CBR

- In situ density

- Portable skid tester

- Macrotexture depth measurement equipment

- Georadar (GPR)

ACTIVITIES SUPPORTING PUBLIC AND PRIVATE BODIES AND COMPANIES IN THE ROAD SECTOR

Thanks to the skills of the ICAR/04 research group, the Road Materials Laboratory can assist its clients in solving specific design and construction problems, in managing disputes and in the scientific coordination of development activities and industrial research.

Third-party activities include laboratory and field tests for the control and verification of materials, pavements and works performed for the construction of road infrastructures. Issued certificates are valid for the verification of construction products (e.g. CE marking).

| Type | Teaching and research laboratory |

|---|---|

| ezio.santagata@polito.it | |

| Staff |

|